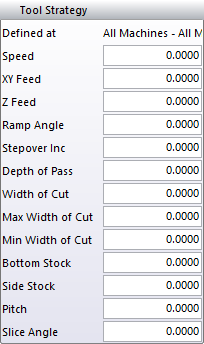

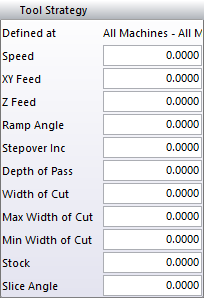

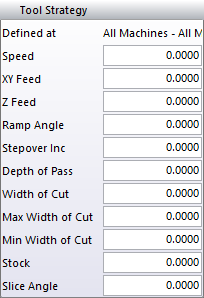

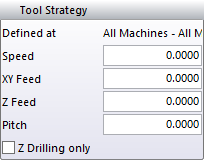

Tool Strategy

In this section the User will define the cutting parameters of the tool. The tool form menus will be different for each style of tool. The GunDrill Tool will also have a section called Soft Start will start your drilling cycle at a slower speed and feed for a specified distance and progressively get faster.

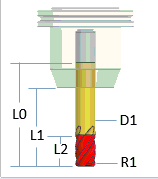

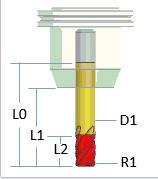

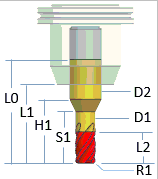

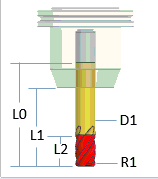

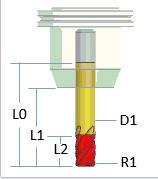

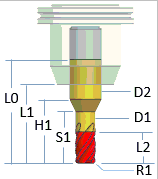

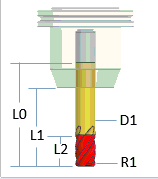

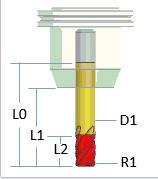

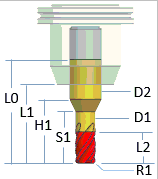

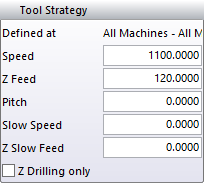

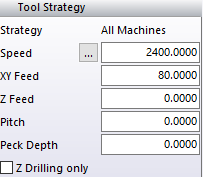

| Standard 2D Tool | Standard 3D Tool | Double Shank Tool |

|  |  |

|  |  |

| Conical Tool | Drill Tool | Tap Tool |

|  |  |

|  |  |

| Thread Tool | Gundrill Tool | Double Shank Drill Tool |

|  |  |

|  |  |

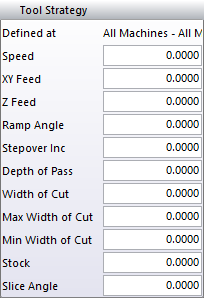

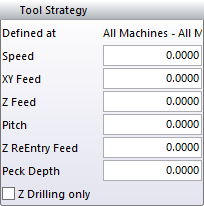

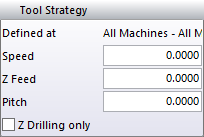

Below is a description of all the parameters used when defining tools Speed – will be your spindle RPM

XY Feed – is the XY-axis feedrate

Z Feed – is the Z-axis feedrate

Ramp Angle – the angle you wish the cutter to decent on

Stepover Inc – is the amount you wish to step over in a lace cut operation

Depth of Pass – the amount you wish to take for each Z-level pass

Width of Cut – is the amount of a step over in the XY plane for Z-Level pass style toolpaths.

Max Width of Cut – the maximum width of cut that can be taken with the cutter

Min Width of Cut – the minimum width of cut that you would like to take with the cutter, in the Z-cut Solid strategy it will be the radius of the cutter

Bottom Stock – amount of stock you wish to leave at the bottom of a pocket

Side Stock – amount of stock you wish to leave on the sides of a pocket

Pitch – for a 2d operation like a helical, it is the distance that the Z-axis will travel in one rotation of the hole. In a threading operation it is the pitch of the thread you are trying to achieve.

Slice Angle – this is the angle you wish the cutter to travel on when making a Lace cut strategy

Z ReEntry Feed - the feed rate you would like the drill to reenter the hole after it clears the chip in a Pecking Cycle. If you leave this value at 0.000 it will rapid back into the hole.

Peck Depth – for drills, the amount you would like the drill to travel in the Z-axis before it comes out of the hole to clear the chip.