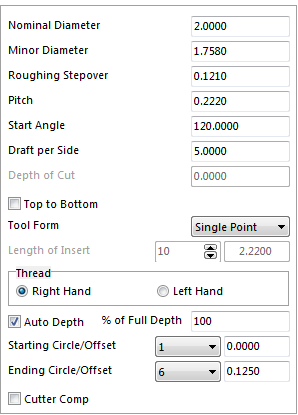

Thread

This program uses a thread milling tool to put in threads. There are three different tools to pick from and options for each tool.

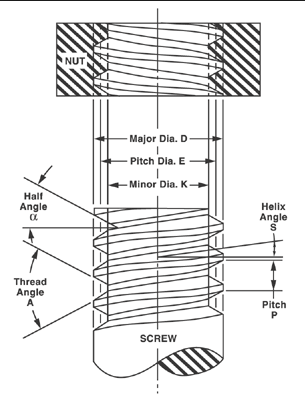

Below is a diagram of a thread to show the meanings of the terms used.

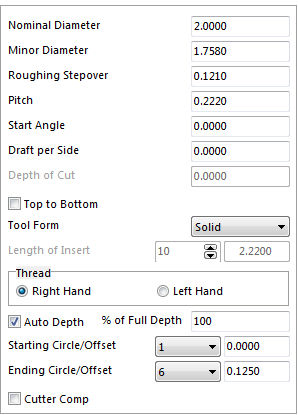

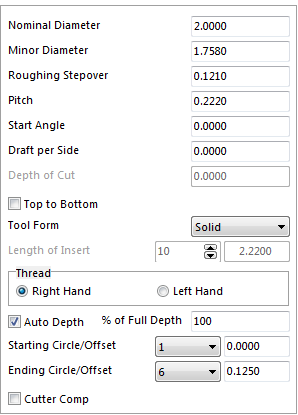

Nominal Diameter

Enter the finish or Major Diameter for an internal thread.

Minor Diameter

The diameter required to start to calculate from and work its way outwards the Nominal Diameter.

Roughing Stepover

The amount of material for the cutting tool to take at once as it is making its way to the Nominal Diameter. In this case it is going to take .121 per pass and take two passes.

Pitch – the distance between the threads is illustrated in the diagram below.

Start Angle

Is mainly used for making the thread start at a specific point. Calculate where it needs to start and input the appropriate angle. The user can have it pick up or chase an existing thread. Inputting that angle will get you close but you may still need to adjust your Z height to get it to blend in.

Draft per Side

To put draft on the thread input the angle per side required. For example, if the user is putting in a NPT thread input 1.7833. Enter the angle required.

Top to Bottom

The threading program will always start at the bottom of the hole. This way it will climb cut on its way out for a right hand thread. If a left hand thread is required and the user wants the tool to climb cut, check the box for the tool to start at the top of the hole and work its way down.

Thread

Select whether a right hand or a left hand thread is required.

Auto Depth

With this option checked select the starting circle and the final ending circle. There is an option for the system to only go a % of the depth. Enter the percentage of the depth required. With Auto Depth unchecked the options change. Enter what circle to start from and how deep to go from that circle under Depth of Cut.\

Start Circle/Offset

Is used to tell the system which circle to start from and give it offset to start higher or lower than the start circle. Enter a positive number the tool will start higher than the start circle. Enter a negative number and the tool will start below the start circle.

Ending Circle/Offset

Is used to tell the system which circle to start from and give it offset to start higher or lower than the start circle. Enter a positive number the tool will start higher than the start circle. Enter a negative number and the tool will start below the start circle.

There are three different types of tools in the following selection and each one will react differently.

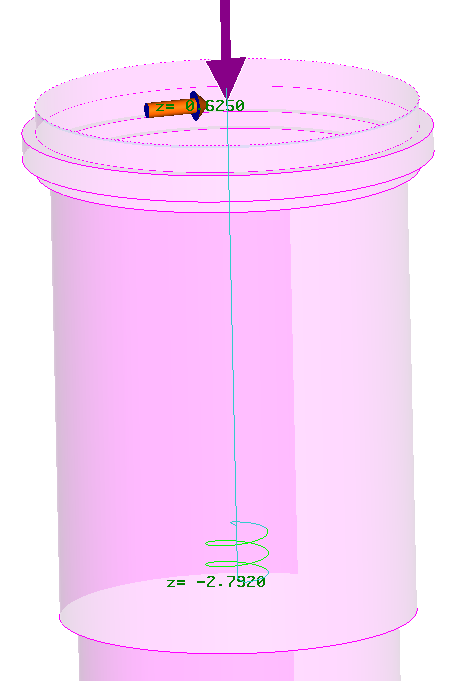

Solid

A Solid tool will start at the bottom and work its way to the top of the hole. The tool will go around twice and then exit the hole. The thread will be cut all the way to the top of the hole.

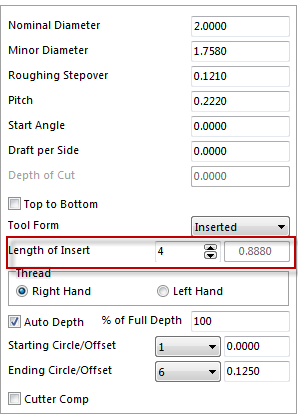

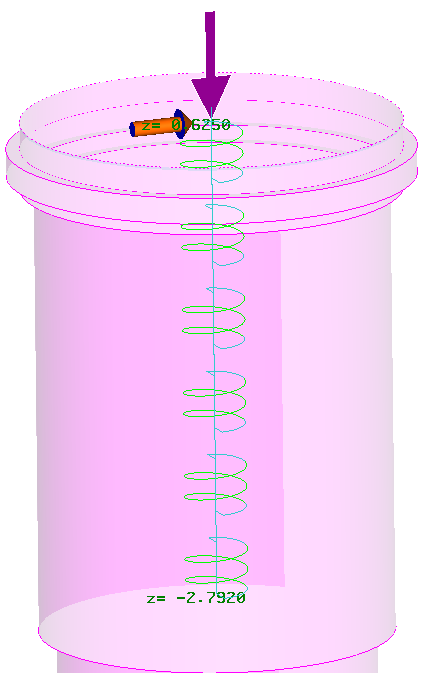

Inserted

In this example we are using an Inserted Tool. \\When doing so another set of parameters appear.

Length of Insert

Input the number of teeth on the insert and the system will know the distance it needs to travel to achieve a full thread.

The tool will do three different passes at different heights to achieve a fully threaded hole. It will start at the bottom of the hole and work its way to the top. When it moves from one height to the other it will not retract out of the hole, it will only come up to the next height.

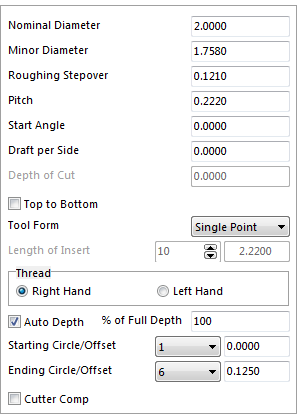

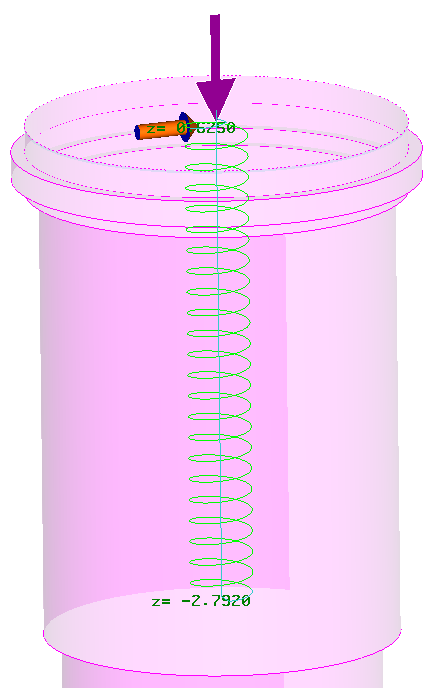

Single Point

A Single Point tool will start at the bottom and work its way to the top of the hole. This tool it will go the length of the hole.

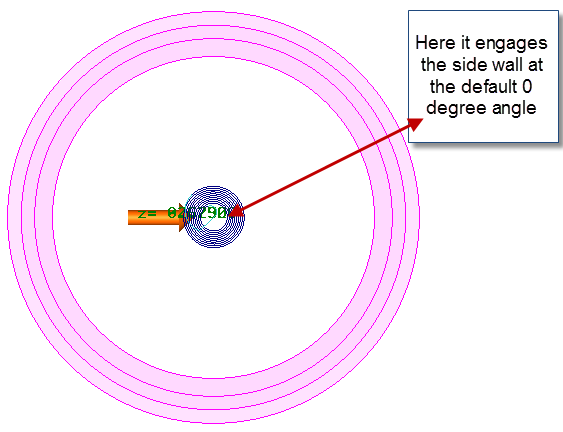

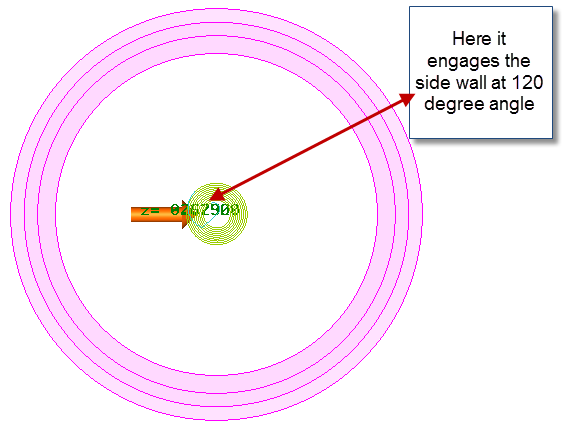

Example of how the Start Angle and Draft per Side works

A Start Angle of 120deg and a Draft per Side of 5deg. The next example will show one at a 0deg \\Start Angle and one at 120deg Start Angle.

Illustrated below is a 0-degree Start Angle. The angle starts to the right of center of the hole and it works its way counter clockwise to 360 degrees.

Illustrated below is the 120-degrees Start Angle. The angle starts at 120 degrees from 0-degrees which is to the right of center.

The system will calculate the depth by using the distance it takes to get from the Nominal Diameter to the Minor Diameter and use that as the depth of the hole. If it is required to go deeper change the Minor Diameter to go deeper or shallower.