Pocketing Tab

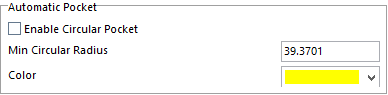

Color – this is the default color of the pockets that are made by using the auto pocket detection option.

Color – this is the default color of the pockets that are made by using the auto pocket detection option.

Enable Circular Pockets – when you use the auto pocket detection option with this box unchecked it will not detect circular pockets.

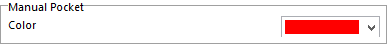

This is the default color of the pockets that are made manually.

This is the default color of the pockets that are made manually.

This is the default color of the pockets that are made manually.

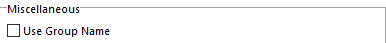

Use Group Name – this option “used” to ask for a group name (like a window name) used in the group name column in the pocket manager

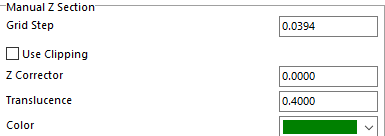

Grid Step- Size of Grids when using the Manual Z sectioning or Flat Z sectioning.

Z-Corrector-

Translucence- Translucency of the pockets created in Manual Z sectioning.

Color- Color of Manual Z pocket

These setting are specific to the Pocketing tab.

A translucent plane will appear showing the user where the Z level of security plane is. The user can adjust the plane by clicking on the Pick button and selecting a point, use the slider bar to adjust it to where it is needed or type in a number.

The color of the plane can also be changed by using the drop down menu on the far right side next to the Pick button. It can also be turned on and off by checking or unchecking the box next to the name on the far left side.

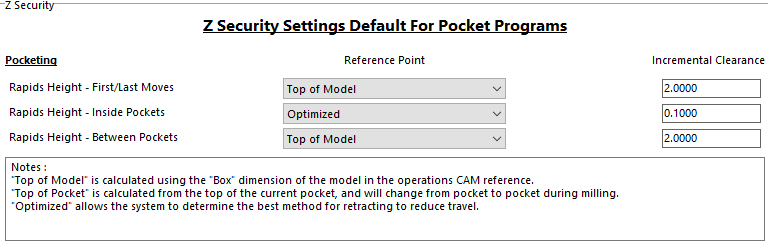

There are three ways the user can control how the tool will retract travelling from one area to the next. Once you have set these values and the type of Optimization, these settings will be the default for future programs made under the 3D Milling tab.

Optimization Type – there is a drop down menu here that will give three options.

Top Of Model- is calculated using the “Box” dimension of the model in the operations CAM reference.

Top Of Pocket- is calculated from the top of the current pocket and will change from pocket to pocket during milling.

Optimized- allows the system to determine the best method for retracting to reduce travel.