Mill Tab

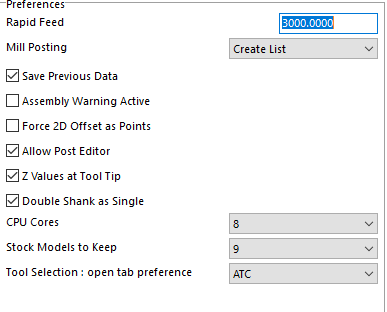

This command displays a list of commonly used parameters used when defining milling operations. These parameters may be attributed default values in order to gain on input time when defining a new operation. When displayed in the milling process, these values may also be overwritten.

Here are some of the important ones to know.

Save previous data- Saves information from one session to another.

Assembly Warning Active- Alerts when there is a collision with the assembly.

Number of CPU Cores – if you are using a multi core computer make sure to set the number of cores available for faster calculation, there is only a maximum of 8.

Stock Models to Keep – this is the number of stock mill updates that you can undo, there is a maximum of 9.

Tool Selection: Open Tab Preference- Defaults what is active when selecting a tool.

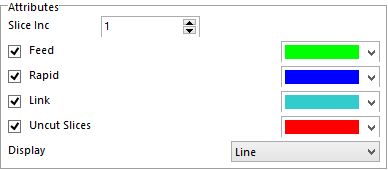

These are where you can set the defaults of how the cutter path is displayed.

Here is where you will set the defaults of the cutter path auto naming.

User Prefix – you can have the auto naming have a Prefix for example the machine name

Boring Mill1-001

User Start Number – this number is where the auto naming will start.