Table of Contents

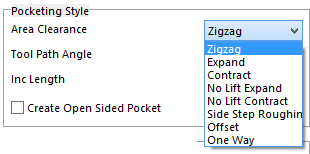

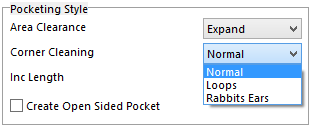

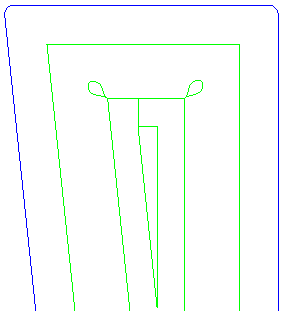

Pocket Style Section

In this section the user will let the system know how to remove the stock at the center of the pocket. Beside the Area Clearance there is a pull-down menu with eight different options to clean out the center of the pocket. All are fast and efficient, and it is up to the user to decide which is best for the application. With each style there is an option of creating one side of the pocket as an open face to allow the tool to clean the pocket right off the side of the work piece. The Inc Length works with this option. An example will be highlighted after we explain the other options.

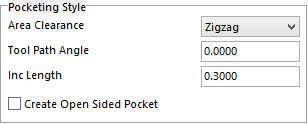

Zigzag Style

With the Zigzag the user will have a single parameter to enter.

With the Zigzag the user will have a single parameter to enter.

Tool Path Angle – this will determine the angle that the tool will travel to remove the interior stock. Any angle can be used from 0.000 to 360 degrees.

To fill in the Tool Path Angle, 0.000 is horizontal with the screen and working counterclockwise is the way the angle will go as the number is increased.

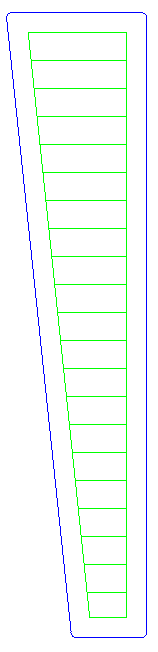

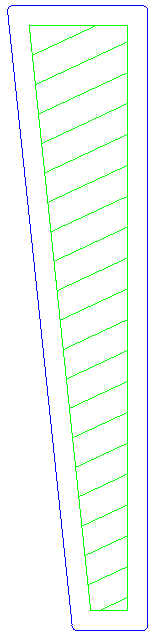

Picture on the left was made at 0,000 Tool Path Angle|Picture on the right was made at 25.000 Tool Path Angle

Picture on the left was made at 0,000 Tool Path Angle|Picture on the right was made at 25.000 Tool Path Angle

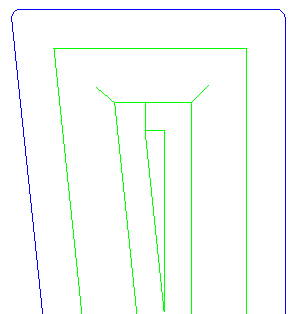

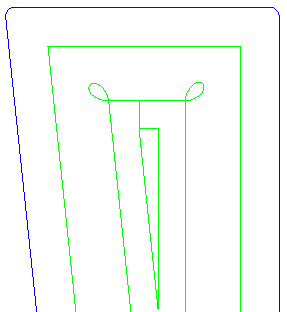

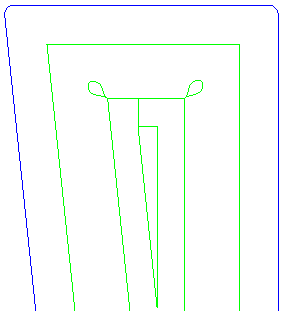

Expanded Style

With the Expanded the user will choose one of three parameters. Each one of these parameters will clean the interior corners differently as shown in the examples below. With the Expanded Style the toolpath will start in the center of the pocket and work its way to the outside.

Normal

Normal

Loops

Loops

Rabbit Ears

Rabbit Ears

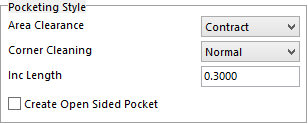

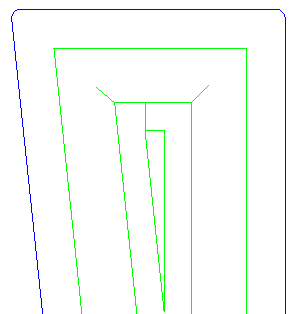

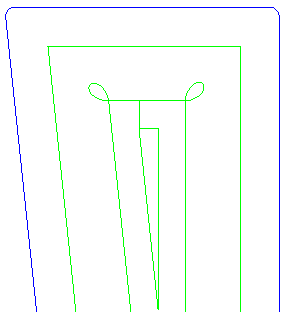

Contract Style

With the Contract the user will need to set one of the three parameters. Each one of these parameters will clean the interior corners differently as shown in the examples below. With the Contract Style the toolpath will start at the sidewall of the pocket and work its way to the center.

Normal

Normal

Loops

Loops

Rabbit Ears

Rabbit Ears

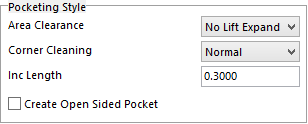

No Lift Expand Style

This style is similar to the Expand Style. The difference is if there is an object or obstruction in the way of the toolpath it will not retract to the safety plane and go over it. The toolpath will optimize itself and stay on the steel to get around it.

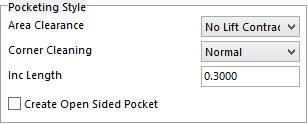

No Lift Contract

This style is similar to the Contract Style. The difference is if there is an object or obstruction in the way of the toolpath it will not retract to the safety plane and go over it. The toolpath will optimize itself and stay on the steel to get around it.

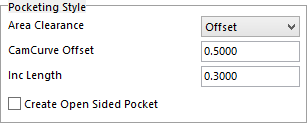

Offset Style

This style will help to finish pockets that have been casted into the work piece by allowing the user to enter an offset that will start at the inside of the pocket and work its way to the side of the pocket. The Cam Curve Offset needs to be at least 70% of the tool diameter in order for it to work.

In this example a 1.000 diameter tool and an offset of .750 is used. The program will start towards the center of the pocket then step over towards the sidewall of the pocket. It will do this by levels.

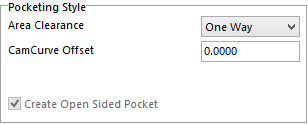

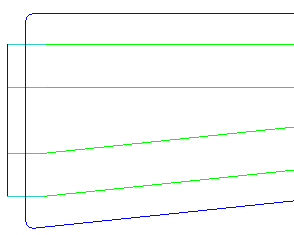

One Way Style

As shown in the diagram below this style will profile the walls of a pocket. The pocket needs to have an open side because it will start off the steal and only climb cut. An offset value can be entered to have it do more than one pass. The offset value needs to at least be 70% of the cutter diameter.

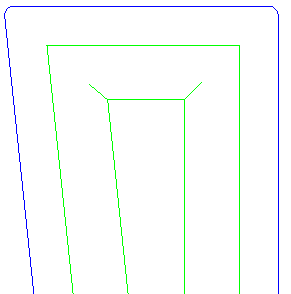

Create Open Sided Pocket

If your pocket is breaking out the side of your work piece you can have it go outside of the block so that you do not leave a scallop of the radius of the tool on the edge of the block. Simply check the box and use the Inc Length to a value that you wish your tool to go off the block by taking the radius of the tool and add to it the amount you want it to go off the steel.