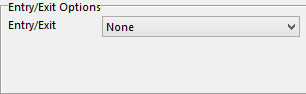

Entry/Exit Options

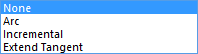

The Entry/Exit Options has a drop down menu that consists of four options shown here.

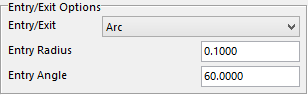

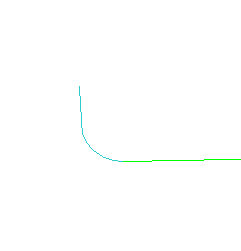

Arc– this option will arc the tool into the material. Once this option is selected the user will need to fill in parameters for Entry Radius and Entry Angle.

Entry Radius – enter the value for the tool to arc in and out at.

Entry Angle – enter a value of an angle for the tool to start at. 0 degrees is parallel to the side wall and 90 degrees is perpendicular to the side wall.

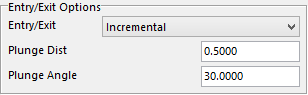

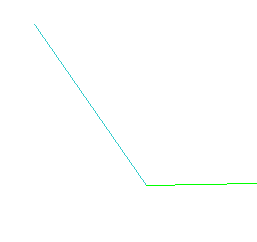

Incremental – this option will allow the user to have a straight line from the contact point of the tool to the steel. The user will need to input values for the Plunge Dist and Plunge Angle.

Plunge Dist – this value is the amount the tool will travel before the contact point.

Plunge Angle – this value is the angle the tool will approach the contact point. It will also rotate about the contact point.

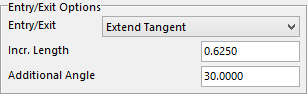

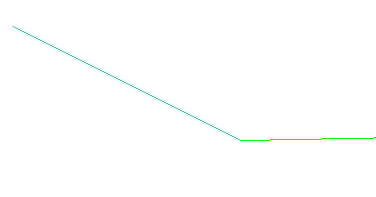

Extend Tangent – this option will allow the user to have a straight line that will be tangent to each passes start point. The user will need to input values for the Incr. Length and Additional Angle.

Incr. Length – this value is the amount the user wants the toolpath to extend past the start point of the toolpath.

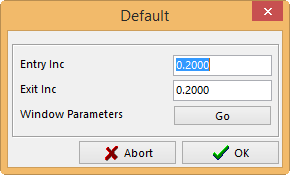

The Default button will have additional options and values that can be changed.

Entry Inc – this value is the distance that the toolpath will rapid to above the start point of the pass before going into feed motion.

Exit Inc – the distance the program stays in feed mode when it lifts from the steel.

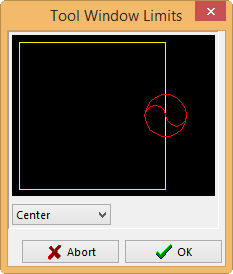

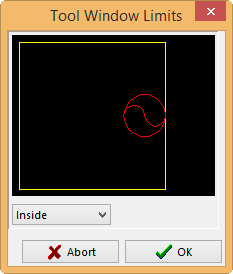

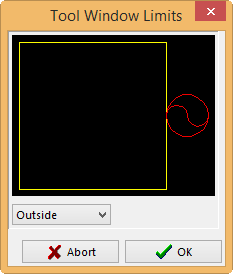

Window Parameters will let the system know how the user wants the tool to make contact with the window used. There are three options.

Center – this will let the system know that the user wants the center of the tool to be on the edge of the window.

Inside – will let the system know if the user wants the tool to stay completely inside the window.

Outside – will let the system know if the user wants the tool to go just to the outside on the window.